How to Choose the Right Printer for Sportswear

)

Ensuring sports clothing looks the part is only half the battle, with manufacturers also having to ensure these products perform well and retain their sharpness. Rob Fletcher looks at how printer choice can play a major role in the success of printed sportswear.

When it comes to garment printing, ultimately it is the look of the final product that is the most important aspect for the consumer. However, when it comes to sportswear, there is another major consideration to keep in mind: how the piece of clothing will perform under intense use.

After all, sportswear is subject to much more wear and tear than many other garments. This could be a specialist running top facing up against the elements, or a football shirt that has to be washed several times a week to clean off mud from matches and training.

For printers delivering printed sportswear, they must consider the type of printer they are using to ensure the pieces they create will look as fresh as when they came off the printer months, and even years, down the line.

So, what should printers be on the lookout for when investing in print technology for this line of work?

Long-term investment

Up first to advise on the subject is Mimaki. Marc Verbeem, product management supervisor, said sportswear needs to be able to withstand repeated washing and wear. He added that high quality print on a high-quality printer ensures that printed logos and designs remain intact and vibrant.

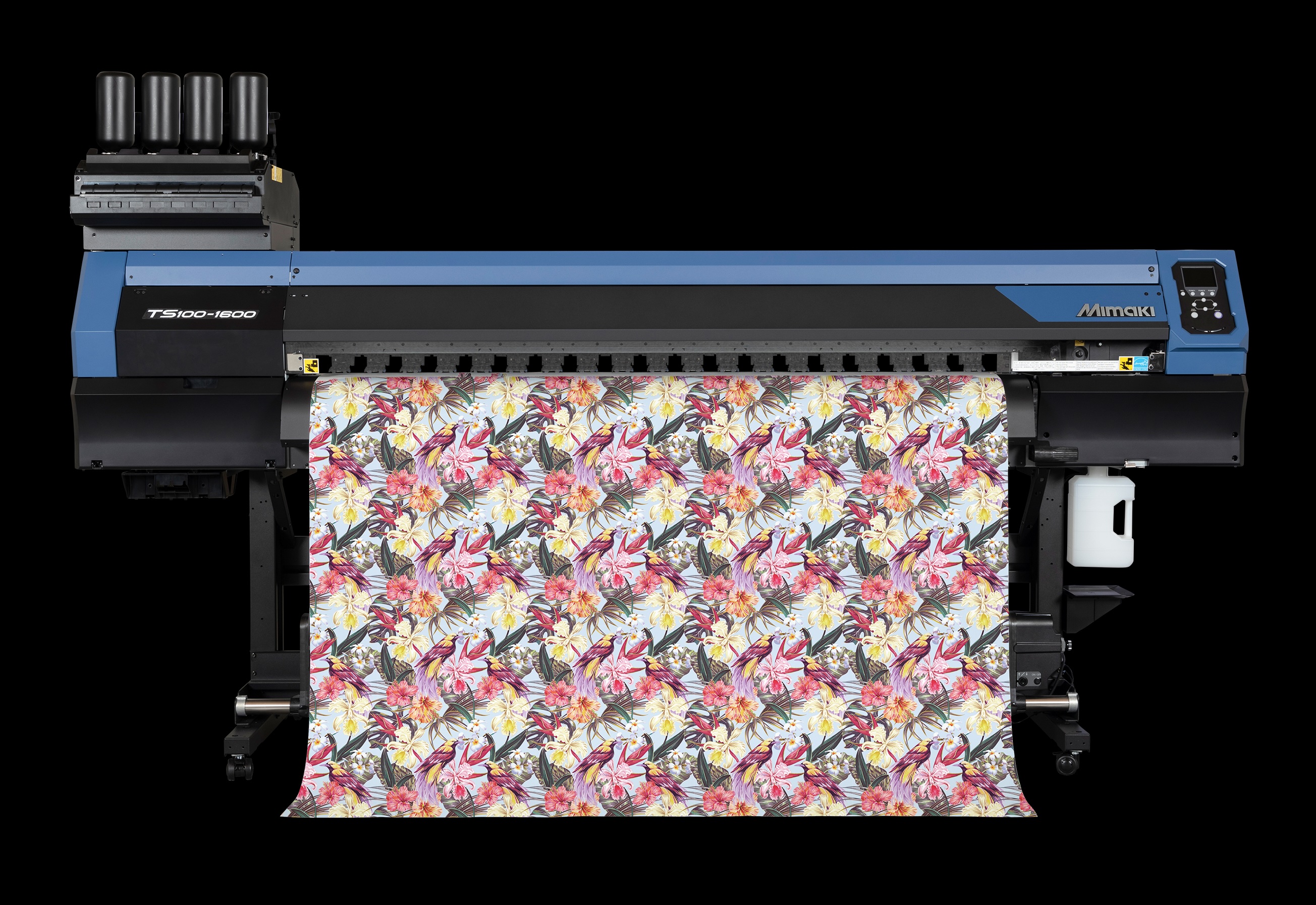

Caption: Mimaki recently launched its new TS100-1600 as an entry-level option. Credit: Mimaki

For sportswear, Mimaki offers a range of sublimation printers, the latest being the entry-level model TS100-1600. It also has the high performance TS330-1600 and the industrial-volume Tiger600-1800TS.

Verbeem said the TS100-1600 offers an entry-level option for those starting out in textile printing, providing durability and high colour intensity. Meanwhile, he said the TS330-1600 dye-sublimation printer allows users to produce a variety of vivid ink colours, including fluorescents, ideal for sportswear applications. In addition, he said the industrial Tiger600-1800TS is geared towards handling high-volume textile projects, all while maintaining high-speeds and top-notch quality.

“With several high-profile sporting events taking place this year, including the Olympic Games in France, opportunities in the printed sportswear market remain high,” Verbeem said. “Mimaki has had a lot of experience in this sector, with a leading portfolio of dye sublimation printers, created to align with emerging textile trends and needs of the market. These range from personalised and customised sportswear, including printed designs and logos, to the continued popularity of ‘athleisure’ for both casual and sport use.”

With this, Verbeem went on to pick out several other factors that he said PSPs need to be aware of in terms of wider trends in sportswear production. These include sustainability, which he said has become a primary consideration for all sectors.

“Offering a more environmentally friendly printing solution is key to aligning with consumer and company values,” Verbeem said. “On-demand digital printing requires no inventory, reduces waste, and allows for much lower energy consumption.”

As for the type of work PSPs should look to target within the market, Verbeem highlighted personalisation, saying this offers a cost-efficient and lucrative avenue in the sportswear sector.

“Due to today’s technological advancements, both in digital printing and e-commerce, it is increasingly easy for companies to offer customisation services,” he said. “Also, particularly for this year, there are significant opportunities across different markets due to current sporting events – such as the Olympics – including corporate merchandise.”

Brimming with potential

Also offering guidance here is Kornit Digital. Anna Holmes, business development manager of athleisure and sportswear, said the sportswear market is brimming with potential but constrained by traditional practices. However, Holmes also said the market is on the cusp of a significant transformation.

“With consumers demanding personalised, high-quality products that don’t compromise on performance, there’s a pressing need for disruption,” Holmes said. “This is where our tech plays a pivotal role.

Caption: Kornit Digital said quality of print is critical when working with high profile brands on sportswear items. Credit: Kornit Digital

“We’re enabling businesses to meet consumer needs at the point of purchase through AI-powered creativity and limitless design possibilities. In doing so, we're bridging the gap between the digital and physical worlds, empowering brands to launch products in the metaverse that can then be purchased, manufactured, and delivered locally as the demand follows.”

So, what sort of printer should PSPs be looking to invest in to take advantage? Holmes said quality is “non-negotiable” when it comes to sportswear printing, explaining top brands such as Adidas, Nike, NBA, NFL, E1 and the UEFA Champions League have built their reputations on delivering exceptional performance.

“Their consumers expect nothing less, especially when investing in merchandise,” Holmes said. “A quality printer not only ensures superior results but also enhances brand value and customer satisfaction, meaning repeat purchase.

“The sportswear market is ripe for disruption and innovation. Young consumers are driving the change, seeking self-expression and vibrant designs. Printers who embrace this shift and deliver high-quality, on-demand printing will thrive in this dynamic industry. Kornit Digital is here to support them every step of the way.”

Caption: XDi technology from Kornit Digital mimics other decoration techniques with a high build of print. Credit: Kornit Digital

With this, Holmes highlighted some of the options available from Kornit Digital in terms of hardware, namely its patented XDi technology. This, Holmes said, adds value to apparel by mimicking other decoration techniques with a high build of print.

“This allows brands to create unique and high-quality sportswear pieces that stand out in a crowded market,” Holmes explained. “Our commitment to technological advancement is unwavering, and we’re constantly exploring new ways to empower brands and disrupt the status quo.

“For brands and manufacturers, we offer a suite of transformative solutions. Our KornitX Fulfilment Network enables brands to expand their global reach with local precision, while our direct-to-garment and direct-to-fabric printers allow manufacturers to redefine their processes and outcomes. These offerings provide the agility needed to respond to evolving trends and stay competitive in an ever-changing market.”

Discover the latest innovations in sportswear at Sportswear Pro 2024, taking place from 19th – 22nd March 2024. Sportswear Pro will showcase the very latest technologies and solutions for on-demand and customised sportswear production. From sample design and automated digital workflows, to innovative materials and integrated wearable technologies, the exhibition and visionary trend forum will present sustainable, faster and leaner production solutions to sports and activewear brands and manufacturers. Register here and use promo code SWPJ402 to save!